SOH1400.40.6 Latest Order Shipping News

Trusted by a Global Industry Leader

A leader with over 65 years of expertise in the pump industry has chosen SOH. Entrusting us with their core production line is the clearest validation of our capabilities.

Engineered for Performance, Trusted by Industry Leaders

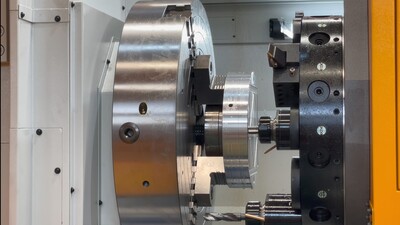

Machine Highlights: SOH Turn-Mill Center

• Multi-tasking Integration: Turning, milling, drilling, tapping, and eccentric machining completed in one setup—boosting overall efficiency.

• High-Rigidity Structure: Built to withstand heavy loads while maintaining long-term stability.

• Full Process Verification Before Shipment: Beyond meeting specifications, every process is tested and validated on-site to ensure performance.

Machine Core Specifications

Swing Over Bed

Ø 1400 mm

Distance Between Centers

4000 mm

Spindle Bore

Ø 6” (152 mm)

Tailstock Quill

Ø 200 mm / MT6

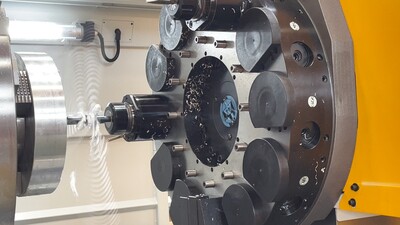

Pre-Shipment Test Runs

Facing creates datum surface

C-axis indexes four flats

Inner-square milling shows precision

Efficient drilling with chip evacuation

Rigid tapping ensures accuracy

C-axis interpolation enables off-center boring

Prior to shipment, every machine undergoes comprehensive performance testing to verify mechanical integrity, functional reliability, and compliance with precision standards.

Technical Highlight Wrap-up

With CF-axis positioning accuracy of 15 arc-seconds (0.004°), SOH ensures reliable interpolation and complex feature machining in a single setup. This capability reduces downtime, eliminates repeated setups, and delivers consistent accuracy for heavy-duty applications.