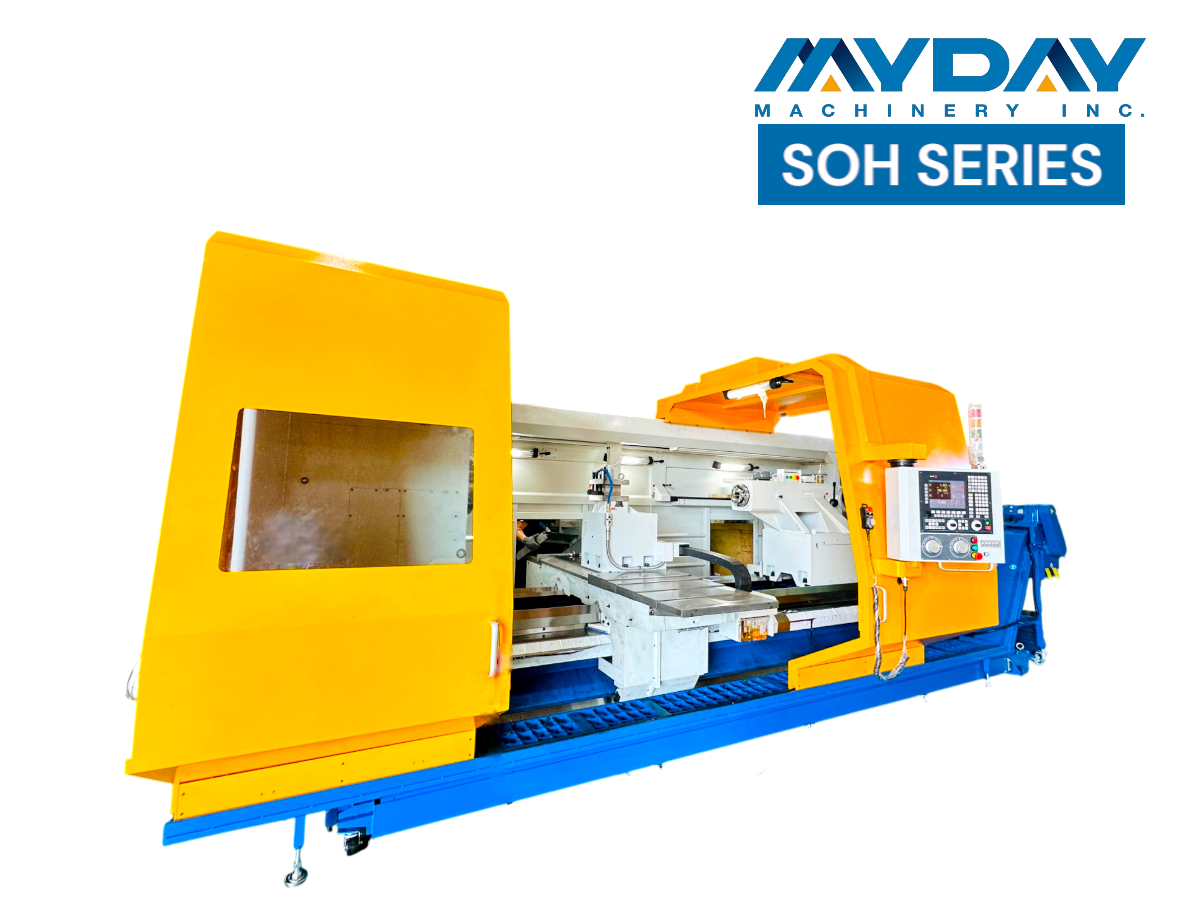

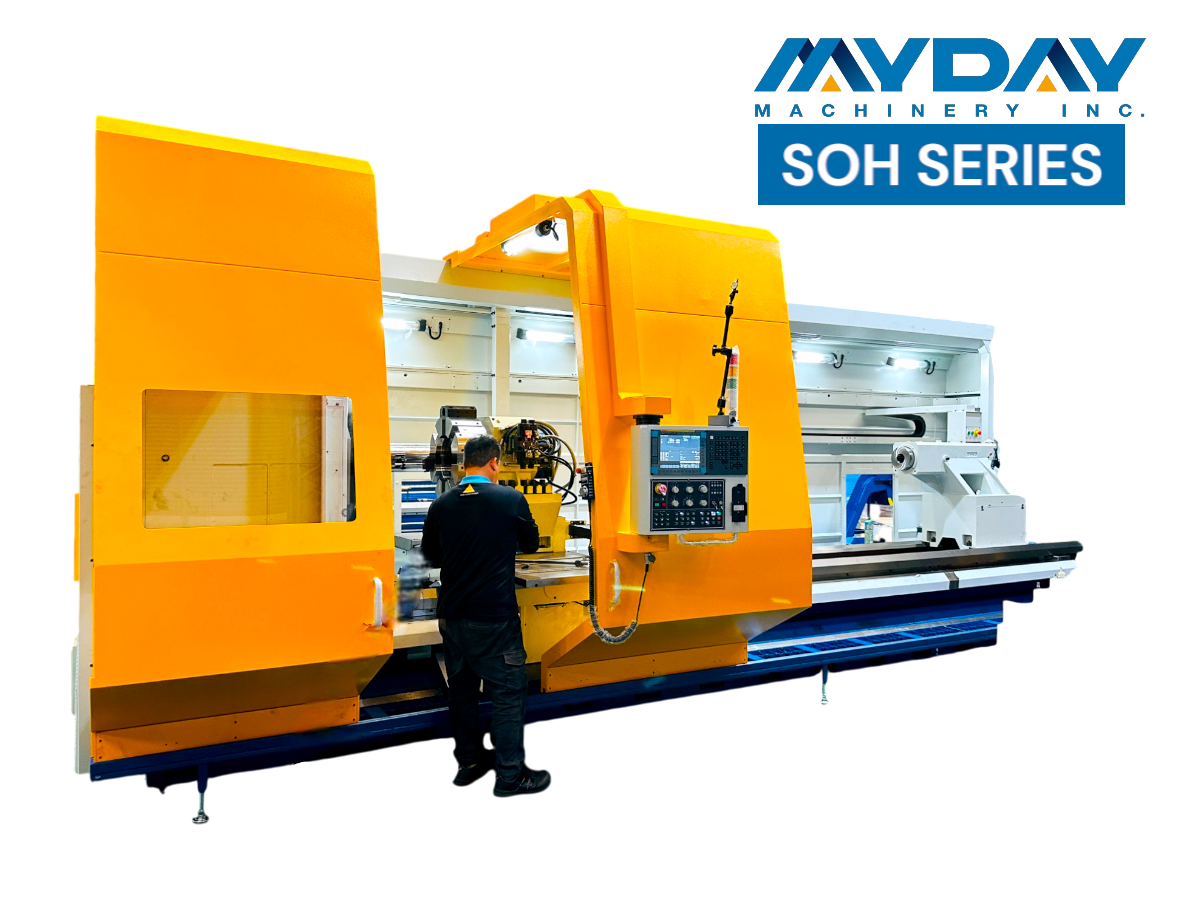

CNC Heavy Duty Oil Country Lathe (32” Bed)

CNC heavy duty oil country lathe is a famous product line for oil & gas field and metal industry. It could be big bore lathe of double chucks at both sides of the headstock, or it could have large swing for big workpiece. It could be applied to oil pipes, big steel rollers, large diameter flanges, long shafts of ships, etc. Besides, for better workpiece clamping, we have rotary quill option on tailstocks.

| Description / Model | SOH1200 | SOH1400 | SOH1600 | ||

|---|---|---|---|---|---|

| Center Height | 600 mm | 700 mm | 800 mm | ||

| Swing Over Bed | 1190 mm | 1385 mm | 1580 mm | ||

| Swing Over Cross Slide | 740 mm | 940 mm | 1140 mm | ||

| Bed Width | 800 mm (1000 mm with Auxiliary Guideway) | ||||

| Distance Between Centers | 2000~10000 mm (80”~400”) | ||||

|

Spindle Bore *Not for SOH1200 |

Ø156mm(6”) / Ø230mm (9”) / Ø260mm (10”) /Ø310mm (12”)* Ø360mm(14”)* / Ø410mm (16”)/ Ø535mm (21”)/ Ø635mm (25”)* |

||||

| Spindle Nose | A2-15 (6”) / A2-15 (9”) / A2-15 (10”) / A2-20 (12”) / A2-20 (14”) / A2-28 (16”)/ A2-28 (21”) | ||||

|

Spindle Speeds (4 Steps) |

6-800 / 4-600 / 4-540 / 3-400 /3-360 / 2-300 / 2-300/ 2-300 rpm |

||||

| Spindle Motor | 30 KW (BC 2~5 M) / 37 KW (BC 6~10 M) | ||||

| Rapid Travel | X-Axis : 5 m/min , Z-Axis : 5 m/min | ||||

| Max, X-Axis Travel | 800mm | ||||

| Max, Z-Axis Travel | 1750~9750 mm(80"~ 400") | ||||

| Tailstock Spindle Travel/Quill | 300mm / Ø200 (Std.) or Ø290 Rotary Quill (Opt.) | ||||

| Tailstock Spindle Taper | MT#7 | ||||

| Controller | FAGOR 8055i | FANUC 0i-TF | SIEMENS 828D | ||

| X-Axis Servo Motor | 3.8 kw | 4.0 kw | 4.85 kw | ||

| Z-Axis Servo Motor | 3.8 kw | 4.0 kw | 4.85 kw | ||

| Coolant Pump Motor | 1 HP | ||||

| 32” Standard Accessories | 32” Optional Accessories |

|---|---|

| CNC Controller: Fanuc, Fagor or Siemens | 3-Jaw Chuck |

| AC Spindle Motor (22KW) | 4-Jaw Chuck |

| Auto Lubrication System | Face Plate |

| Coolant System | Hydraulic Chuck |

| Spindle Oil Chiller | Pneumatic Chuck |

| Electric Cabinet Air Conditioner | Double Chuck System |

| 2-Door Type Splash Guard | Steady Rest |

| Chip Conveyor | Follow Rest |

| Work Light | Heavy Duty Steady Rest (2-Point Type) |

|

Spindle Sleeve and Dead Center (For Spindle Bore ≦ 9") |

Hydraulic or Electric Milling Device |

| Tailstock Center | Hydraulic Spindle Orientation (5 Degree Resolution) |

| Leveling Bolts & Pads | Boring Device |

| Tool Box with Oiler, Spare Fuse, Paint & Tools | Hydraulic 4-Way Tool Post |

| Operation & Service Manual | Hydraulic V8 Turret |

| Hydraulic V12 Turret (for TNC-1200 and Above) | |

| Hydraulic Tailstock | |

| C-Axis Control | |

| Power Turret | |

| Full Guarding |

The specifications listed are for reference only. MYDAY reserves the right to make changes at any time without prior notice."