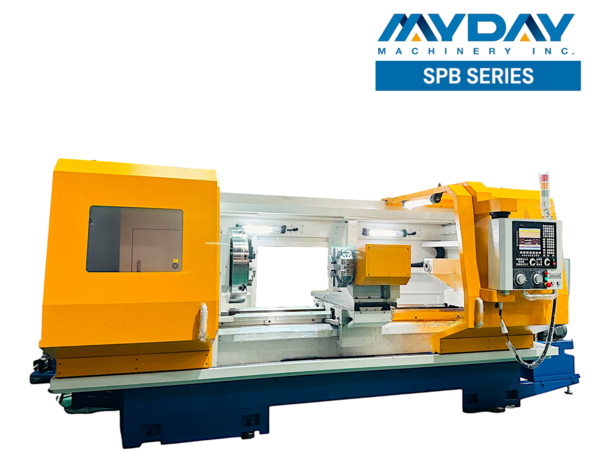

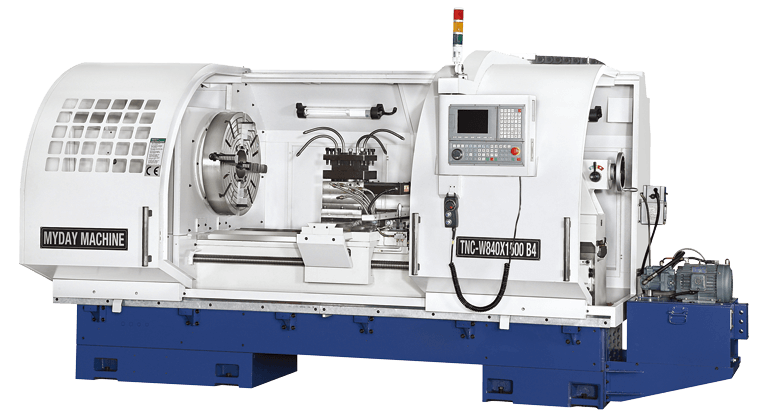

CNC Heavy Duty Precision Lathe(18” Bed)

CNC heavy duty precision lathe is a very popular product line in metal industry. The spindle motor power in the series is transmitted to the spindle through pulley, belt and 4-step gear sets. It could perform heavy duty machining with high speed and high rigidity.

| Description / Model | SPB670 | SPB770 | SPB840 | ||

|---|---|---|---|---|---|

| Center Height | 335 mm | 385 mm | 420 mm | ||

| Swing over Bed | 670 mm | 770 mm | 840 mm | ||

| Swing over Cross Slide | 380 mm | 480 mm | 550 mm | ||

| Width of Bed | 460 mm (18”) | ||||

| Distance Between Centers | 1500~5000 mm | ||||

| Spindle Bore | Ø104mm (4”) / Ø156mm (6”) / Ø230mm (9”) | ||||

| Spindle Nose | A2-11 / A2-11 / A2-15 | ||||

| Spindle Speeds(4 Steps) | 13-1200 / 11-800 / 4-600 Rpm | ||||

| Ball Screw Diameter | X-Axis : Ø32 , Z-Axis : Ø50 | ||||

| Rapid Travel | X-Axis : 5 m/min , Z-Axis : 5 m/min | ||||

| Max X-Axis Travel | 410mm | ||||

| Max Z-Axis Travel | 1300~4800mm | ||||

| Tailstock Spindle Travel / Quill | 230mm / Ø105 | ||||

| Tailstock Spindle Taper | MT#5 | ||||

| Controller | FAGOR 8055i | FANUC 0i-TF | SIEMENS 828D | ||

| Spindle Motor | 15 KW | 15 KW | 15 KW | ||

| Z-Axis Servo Motor | 2.3 KW | 2.5 KW | 2.3 KW | ||

| X-Axis Servo Motor | 1.4 KW | 1.4 KW | 1.48 KW | ||

| Coolant Pump Motor | 0.7 KW (50HZ) / 1 KW (60HZ) | ||||

| 18" Standard Accessories | 18" Optional Accessories |

|---|---|

| CNC Controller: FANUC, FAGOR or SIEMENS | 3-Jaw Chuck |

| AC Spindle Motor | 4-Jaw Chuck |

| Auto Lubrication System | Face Plate |

| Electric Cabinet Heat Exchanger | Hydraulic Power Chuck |

| Coolant System | Double Chuck System |

| 2-Door Splash Guard | Steady Rest |

| Work Light | Follow Rest |

| Spindle Sleeve and Tool Centers | Milling Device |

| Leveling Bolts & Pads | Hydraulic Spindle Orientation |

| Tool Box with Oiler, Spare Fuse, Paint & Tools | Boring Device |

| Operation & Service Manual | Hydraulic 4-Way Tool Post |

| Hydraulic V8 Turret | |

| Hydraulic Tailstock | |

| Chip Conveyor | |

| Electric Cabinet Air Conditioner | |

| Full Guarding |

The specifications listed are for reference only. MYDAY reserves the right to make changes at any time without prior notice."